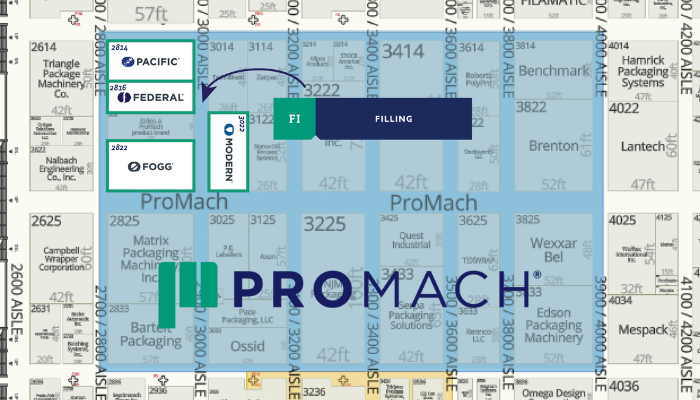

Pack Expo Las Vegas is around the corner! Dive into the world of ProMach filling and enjoy a sneak peek of what our filling brands — Federal, Modern, Pacific and Fogg — are showcasing at the show. Join us in the Central Hall with ProMach to learn more about each product and speak to our sales team to find the best filling machine for your products! If you’re looking for a can filler, visit TechniBlend right across the aisle from us.

Federal: Net Weight & Level Filling Systems

Booth C-2816

NEW Automatic Bulk-FIL™ Tote and Drum Filler

Designed in partnership with Quest Industrial, Bulk-FIL™ integrates a robotic arm to transform the way totes, drums, and jerry cans are filled. The robotic arm automates the entire filling process, including changeovers and cleaning processes. Be one of the first to check out this unique system in person and learn what else it can do!

Xact-FIL® Monobloc

Xact-FIL® is a cutting-edge rotary weight filler and capper monobloc system that combines accurate net weight filling and capping on a single frame, streamlining the production process. The monobloc on display will feature a Zalkin lidding turret. Xact-FIL fillers, along with the rest of Federal’s net weight filling line, offer impressive accuracies of ±0.1%.

Mod-FIL®

Mod-FIL™ is a versatile, accurate modular inline net weight filler for containers from 250mL to 5 gallons that offers seamless integration of 2-station modules as production demands increase. No change parts are needed for container changeovers. It is also available with an optional Class 1 Div 1 explosion proof package.

Simpl-FIL™

Simpl-FIL™ is an accurate and efficient single-station net weight filler designed for startups with low-speed production or lab and testing settings. This machine is designed to fill containers ranging between 2 oz to 5 gallons. It is also available with an optional Class 1 Div 1 explosion proof package.

Modern: Cup & Tray Filling Systems

Booth C-3022

SL Series

Our SL Series custom inline fillers come in many arrangements. Modern is showcasing an SL1x1 for production speeds between 30-40 cups per minute and an SL1x6 with speed capabilities between 180-240 cups per minute. Stop by to see these complete systems and learn more about their capabilities, including container denesting, filling, rollstock heat sealing and cutting, pre-die-cut lid placing and sealing, overcapping, and more.

SR-8DC

This dependable SR-8DC rotary cup filler is the ideal solution for lines requiring 30-40 cups per minute. It offers a compact footprint, impressive capabilities, and reliable operation. The featured model at Pack Expo features denesting, filling, lid placing, heat sealing, and product outfeed.

Die-Cut Lidding Solutions

Beyond packaging machinery, Modern works with PDF Seal to offer high-quality die-cut lids for your products. PDF Seal converts die-cut lids for dairy, beverage, food, snack products, and more. With their outstanding flexographic printing capabilities, you can trust that your product will look great on the shelves. Check out lid samples and meet the team in the Modern booth!

Pacific: Volumetric & Flow Meter Filling Systems

Booth C-2814

Rotary Flow Meter Filler – This model is available for purchase

Our rotary flow meter fillers are available with Dosi Mag or Mass Flow Meters. They have no bottle, no fill capabilities, are extremely accurate, and offer full CIP capabilities. While a standalone filler will be on display at the show, we also offer these systems in monobloc and tribloc arrangements.

Inline Volumetric Filler – This model is available for purchase

Our inline volumetric fillers support light, foaming and viscous applications. We offer bottom up and top filling capabilities and two-phase filling. This system is designed with individual Allen-Bradley servo controlled pump drive systems. Known for their reliability, Pacific fillers offer a low long-term cost of ownership.

PackWest Model 200

PackWest cappers are known to be extremely durable and efficient. PackWest is exhibiting a Model 200 capper at Pack Expo this year. With speeds up to 250 cpm, these cappers are reliable and versatile.

Fogg: Gravity Level Filling Systems

Booth C-2822

F6.2 Filler

Fogg is showcasing a F6.2 filler model which features a 6 ft filler bowl with 30 filling valves. This is designed to fill 52 oz bottles of fresh juice at 160 bottles per minute. Depending on your application, this size Fogg filler can reach 540 bpm on single serve bottles.

Extended Shelf Life (ESL) Technology

Sanitization is always a concern when filling, but it becomes extremely important when filling cold juice and Extended Shelf Life (ESL) products. Because you can’t use heat to kill microorganisms, you have to make sure to kill them before they ever come in contact with your product. Come see Fogg’s bottle sanitizer, bottle rinser, trough system, HEPA filtration, and Sanibar® system which are all ESL features to keep your filling process as sanitary as possible.

Articulating Jaw Capper

Fogg’s Articulating Jaw Capper is the ideal solution for the largest variety of capping needs. The articulating jaws act like fingers and can securely grab onto even the most unique cap with precision. The capper showcased can cap up to 40 caps/min/head.

Microb-Blaster® Bottle Sanitizer

Fogg’s rotary bottle sanitizer carries bottles through a vigorous wash cycle using the customer’s solution of choice. The rinsing process effectively removes loose debris and allows sanitizing solutions to contact all exposed surfaces to kill microorganisms inside bottles before rinsing.

Dual Turret Bottle Rinser or Pre-Fill Bottle Sanitization

Fogg’s dual turret rinser provides rinsing turrets for maximum contact time and the highest level of sanitization. The bottles are sprayed externally and flipped upside down and rinsed with the customer’s solution of choice. Bottles then go through a second turret and are able to be rinsed with two different medias.

Universal Bottle Handling

This universal bottle handling technology significantly reduces changeover time between bottles, reduces the need for storage, and can accommodate bottles of different shapes, sizes, and materials. It uses expandable guides and color-coded keys designated for each different bottle, for clear and simple changeover. Stop by Fogg’s booth to try a changeover on our display table.

Free Registration through September 10th

Are you excited to attend Pack Expo Las Vegas? Click here to register for free using our code: 37Q83. You can find all the latest technology in processing and packaging innovation with ProMach at Pack Expo. We’re looking forward to seeing you there!

Leave a Reply